Industrial hoses for demanding industrial applications: custom-made solutions from Westwood

Industrial hoses are as much a “given” in many plants as piping, valves, or pumps—until a leak, an unplanned shutdown, or a safety incident occurs. At the latest then, it becomes clear how critical the right hose technology is for stable and safe operation.

Westwood is not a B2C shop and not a local retail outlet, but a technical partner for industrial customers—from major food manufacturers and chemical plants to demanding applications in aerospace, mechanical engineering, and energy. The focus is on industrial specialty hoses, custom hoses, and individually assembled hose lines that are precisely matched to the medium, temperature, pressure, and installation conditions.

If your project requires tailored hoses instead of standard products, Westwood is the right partner—by phone at +49-231/4440242 or by email at info@west-wood.de.

You can find an overview of the complete product range here.

Role and Fundamentals of Industrial Hoses

Functions of Industrial Hoses in Industrial Systems

Industrial hoses perform three key functions in industrial processes:

- Conveying and transporting liquid, gaseous, or solid media

- Extracting dust, vapors, chips, or bulk materials

- Compensating for movement, vibration, and installation tolerances between rigid system components

Unlike rigid piping, hoses compensate for length changes, vibrations, and assembly tolerances. In many plants they are also used wherever flexibility is required: at filling stations, moving components, tank vehicles, or mobile units.

Typical Media and Operating Conditions

Industrial hoses—or more generally: technical hoses—must meet a wide range of requirements. Examples:

- Liquid media: water, oils, greases, solvents, acids, alkalis, foods (milk, beer, wine, juices, sugar- and alcohol-based media)

- Gases: air, inert gases, vapors, exhaust gases, hot air

- Solids: powders, granulates, pellets, grain, cement, sand, chips, glass or metal abrasion

In addition, operating conditions include:

- Operating pressure and, if applicable, vacuum

- Temperature ranges from deep sub-zero to very high temperatures

- Abrasion caused by solid particles

- Chemical stress from aggressive media

- Environmental influences such as UV radiation, ozone, moisture, or mechanical stress

This is exactly where the difference between a simple standard hose and a high-quality industrial hose from a specialized hose manufacturer becomes apparent.

Standard vs. Specialty Hoses – Where Are the Limits?

Standard hose products can work in simple applications—for example, for water, compressed air, or non-hazardous media at moderate temperatures. However, standard solutions quickly reach their limits when one or more of the following conditions apply:

- Aggressive or chemically complex media

- High or very low temperatures

- High flow velocities or abrasive bulk materials

- Explosion-hazard areas (ATEX)

- High hygiene and cleanability requirements (food, pharmaceutical)

- Tight bending radii, strong movement, or vibration

In these cases, industrial specialty hoses, custom hoses, and tailored hose solutions are required—often including individual hose assembly and matching fittings.

Typical Applications: From the Food Industry to High-Temperature Processes

Industrial hoses are used in almost all industries. Westwood focuses on industrial applications where safety, hygiene, temperature resistance, or chemical resistance is paramount.

Food Hoses and Hygiene Standards

In the food industry, hose assemblies must do more than simply transport media. Among other things, they must:

- Be hygienic and easy to clean (CIP/SIP)

- Be taste- and odor-neutral

- Comply with relevant standards and recommendations (e.g. EU 1935/2004, FDA, BfR)

- Be permanently suitable for fatty, alcoholic, or high-sugar products

For these applications, special food-grade hoses are used—for dairies, breweries, beverage producers, filling plants, and tank vehicles.

Further information on hose solutions for media with special requirements can be found in the product overview:

https://www.west-wood.de/uebersicht/

Chemical Hoses for Aggressive Media

In the chemical and pharmaceutical industries, hoses often must:

- Be highly resistant to acids and alkalis

- Handle solvents, oils, or other aggressive media

- Remain leak-tight and safe even under changing temperature profiles

- Be suitable for use in explosion-hazard areas (e.g. ATEX zones)

Chemical hoses with special inner linings such as PTFE are frequently used here, offering very high chemical resistance. Westwood supports customers in selecting the right chemical hose based on medium, concentration, temperature, and operating conditions.

Details on suitable hose types for chemical applications can be found here.

High-Temperature and Extraction Hoses in Harsh Environments

Robust hose systems are required for high process temperatures, hot gases, exhaust gases, or steam. Examples include:

- Stainless steel corrugated hoses for high temperatures and pressures

- Extraction and conveying hoses made of specialized, heat-resistant materials

- Heat protection fabrics and sleeves to protect hoses and lines in hot areas

Westwood offers a wide range of solutions—from heat protection products to V4A stainless steel metal hoses.

More information on these products:

https://www.west-wood.de/hitzeschutz/

https://www.west-wood.de/va-wellschlaeuche/

High-temperature materials up to 1,400°C continuous operating temperature

Westwood GmbH offers a broad portfolio of solutions—from heat protection products such as tapes, hoses, cords, packings, and fabrics. Insulation cushions are also assembled according to customer specifications.

INDUSIL® 1,000°C

High-temperature-resistant SiO² products from the USA, available as tapes, cords, hoses, and fabrics.

INDUSIL® products are non-combustible and resistant up to approx. 1,000°C (short-term up to 1,200°C).

INDUSIL® products are free from ceramic fibers (RCF free) and safe for health.

INDUSIL® is used to manufacture insulation blankets, welding covers, heat protection curtains, packings, tapes, and cords. INDUSIL® is a registered trademark of WESTWOOD GmbH (formerly marketed under the name Siltemp).

Thread curtains

Thread curtains open only as much as absolutely necessary when material passes through. The opening remains small, limited to the size of the passing object, and closes immediately afterward. This ensures that heat and atmosphere (e.g. protective gas) remain where they belong in furnaces, dryers, shrink tunnels, etc. The use of thread curtains can significantly reduce energy costs.

Materials:

E-glass / +550°C

HAT 700 / +750°C

SiO² 96% / +1,000°C (INDUSIL®) short-term up to 1,200°C

Dimensions: Free thread height max. 700 mm, otherwise according to customer requirements.

Thread curtains flyer (PDF)

Stitching is done using wire yarns resistant up to 1,000°C. Free thread length + header height (standard 50 mm) = total length (max. 750 mm).

Width as selected by you (segmentation at no extra charge). For an information quote, we require your operating temperature, the dimensions (width and total height including header), and the required quantity. Please feel free to contact us with any questions.

Heat-resistant fiber mats up to 1,400°C (also available in bio-soluble quality)

More information on these products:

https://www.west-wood.de/hitzeschutz/

Anyone who needs to convey or extract aggressive bulk materials or dusts (e.g. in silos, filter systems, dust extraction systems, woodworking or metalworking operations) also requires highly abrasion-resistant extraction hoses. These are usually specially reinforced and made from highly wear-resistant materials.

Key Criteria for Selecting Industrial Hoses

Selecting a reliable and safe hose involves much more than just the diameter. A good hose manufacturer will always ask for a set of key technical parameters. This forms the basis for the right solution.

Medium, Temperature, and Pressure – The Basic Data

Key selection criteria include:

- Medium: What exactly is being conveyed? (e.g. milk, sodium hydroxide, solvent, hot air, powder, granulate)

- Temperature: minimum, maximum, and temperature fluctuations

- Pressure: operating pressure, pressure peaks, and possible vacuum

- Flow: continuous, pulsating, intermittent

- Abrasion: are solid particles present that may attack the hose wall or spiral?

Even small changes—such as switching from water to hot alkaline solution—can require a completely different hose type.

Standards and Approvals

Many applications require compliance with specific standards and regulations, such as:

- Food contact: EU 1935/2004, FDA, BfR recommendations

- Chemicals: resistance requirements, e.g. based on tables or standards

- ATEX/TRBS 2153: conductive specialty hoses for explosion-hazard areas

- EN standards, e.g. for chemical hoses or other specialty applications

Industrial specialty hoses are often specifically designed for certain standards and applications. Expert consultation with an experienced partner is strongly recommended.

Service Life, Environment, and Cleaning

In addition to medium, temperature, and pressure, other factors are relevant:

- Environment: indoor/outdoor use, ozone exposure, UV radiation

- Mechanical stress: movement, bending, torsion, vibration

- Cleaning: cleaning chemicals, sterilization methods, CIP/SIP processes

- Expected service life and maintenance intervals

Especially in the food and pharmaceutical industries, regular inspections and scheduled hose replacement are essential parts of hygiene concepts.

Example Assignment of Media and Hose Types

The following overview shows a rough mapping of media to typical hose solutions (final selection is always application-specific):

| Medium / Application | Typical Solution (Example) |

| Milk, beer, beverages | Food-grade hoses with FDA/EU-compliant materials |

| Acids, alkalis, solvents | Chemical hoses with PTFE inner lining |

| Powders, granulates, bulk materials | Abrasion-resistant extraction and conveying hoses |

| Hot gases, steam, high temperatures | Stainless steel corrugated hoses, optionally with heat protection |

For detailed technical data and media compatibility, direct consultation with Westwood is recommended.

Would you like to discuss a specific application? Call +49-231/4440242 or email info@west-wood.de—together we’ll identify the right hose solution.

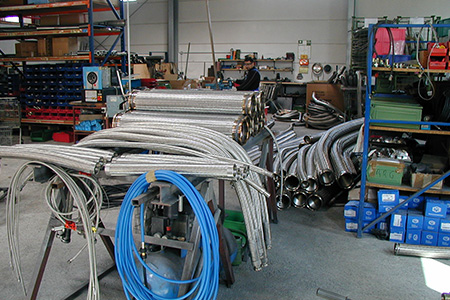

Specialty and Custom Hoses: Individual Hose Assemblies from Westwood

In many projects, standard products are not sufficient—for example because space is extremely limited, special connections are required, or the hose must withstand high temperature, abrasion, and chemicals at the same time. This is where custom hoses, special hose designs, and molded hoses come into play.

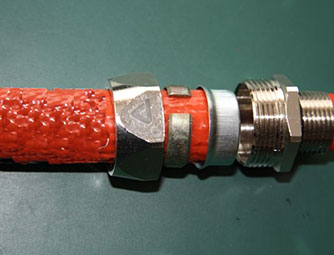

Hose Assembly: From Selection to Fittings

Westwood supplies not only hoses, but complete customized hose assemblies consisting of:

- the suitable hose type (e.g. food, chemical, extraction, stainless steel corrugated hose)

- the right fittings (e.g. threaded fittings, flanges, special connectors)

- optional protection systems (heat protection, kink protection, protective spirals, labeling)

This hose assembly ensures that hose, fitting, and installation are perfectly matched. It reduces leakage risks and makes reordering identical assemblies easier.

An overview of the product range including fittings is available at

https://www.west-wood.de/uebersicht/

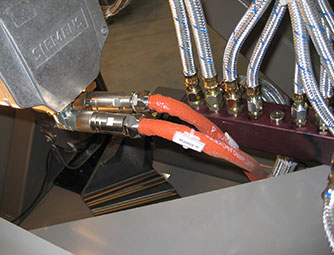

Examples of Customized Hose Assemblies

Typical examples of customized hoses and individual hose assemblies:

- Food-grade hoses with permanently mounted stainless steel fittings for dairies, breweries, or tank vehicles

- Highly abrasion-resistant extraction and conveying hoses for cement plants, silo operations, the woodworking industry, or recycling facilities

- Stainless steel corrugated hoses as flexible connections at high temperatures in power plants, chemical facilities, or high-temperature processes

- Special PTFE hoses (spiral-wound, flexible connections) that meet high visual and mechanical requirements

More information on specialty hose types such as V4A metal hoses can be found here.

Information on special PTFE hoses can be found here.

Advantages of Customized Hoses Over Standard Solutions

Custom and molded hoses offer decisive advantages over standard solutions:

- precisely matched lengths, diameters, and connections

- optimized bending radii and routing

- reduced leakage and failure risks

- longer service life and operating time

- clear labeling and easy reordering

Especially for critical media or high downtime costs, investing in customized hoses pays off.

Safety, Standards, and Quality: Ensuring Reliable Operation

Industrial hoses are safety-critical components. Incorrect selection or design can lead to leaks, product loss, contamination, or, in the worst case, personal injury. Standards, testing, and quality assurance are therefore essential.

Key Standards and Guidelines for Industrial Hoses

Depending on the industry and medium, different standards and regulatory requirements may apply, including:

- EU 1935/2004 for materials and articles intended to come into contact with food

- FDA and BfR recommendations for material suitability in food applications

- EN standards for specific hose types, e.g. chemical hoses

- ATEX and TRBS 2153 for conductive specialty hoses in explosion zones

- industry-specific requirements from pharmaceuticals, chemicals, energy, and other industries

Westwood takes these requirements into account when selecting hose types and provides relevant documents such as declarations of conformity or test certificates.

Testing and Documentation

Safe hose technology typically includes:

- Leak tests and pressure tests for suitable hose assemblies

- Documentation of materials and fittings used

- Labeling of individual hose assemblies (e.g. type, batch, manufacturing date)

- Provision of relevant data sheets and compatibility information

Many applications also require regular visual inspections, testing intervals, or scheduled hose replacement after a defined operating time.

Expansion Joints and Complementary Components

In addition to hoses, expansion joints are frequently used in piping and hose systems. They absorb movement, vibration, and thermal expansion, relieve the hose assemblies, and protect adjacent components.

More information:

https://www.west-wood.de/kompensatoren/

Heat protection products, protective hoses, and fabrics also improve safety by shielding sensitive lines from high ambient temperatures or mechanical stress:

https://www.west-wood.de/hitzeschutz/

From Project to Hose Assembly: How to Work with Westwood

As Westwood is not an end-customer shop, dialogue with the customer is always central. Instead of “click & buy,” the focus is on engineering, design, and reliable hose assembly.

Step-by-Step to the Right Hose Assembly

The path to your custom hose solution typically looks like this:

- Inquiry and application description

- Technical clarification (medium, temperature, pressure, installation conditions, standards)

- Selection of suitable hose types and fittings

- Design and quotation

- Manufacturing and assembly of the hose line

- Testing and quality assurance

- Delivery and documentation

In many cases, close coordination between engineering, maintenance, purchasing, and Westwood specialists proves valuable.

Checklist for Your Inquiry

To help Westwood support you quickly and efficiently, the following details are useful:

- Medium (including concentration for chemicals)

- Temperature ranges (min/max, and cleaning temperatures if applicable)

- Operating pressure and, if applicable, vacuum

- Flow rate or desired flow velocity

- Installation conditions (length, bending radii, movement, existing connections)

- Standards and guidelines that must be met

- Industry and application (e.g. dairy, chemical plant, silo, furnace, etc.)

- Required form (straight hose, molded hose, custom design)

The more precise the information, the easier it is to identify the right solution.

Direct Contact to Your Hose Experts

If you are an industrial customer and require custom hoses, industrial specialty hoses, or tailored hose assemblies, direct contact is the fastest route:

- Phone: +49-231/4440242

- Email: info@west-wood.de

Together with you, Westwood develops custom hoses and complete hose systems that perform technically, meet standards, and provide operational safety. Benefit from the expertise of a specialized hose manufacturer—from the initial idea to the finished, tested hose assembly.